- Home

- ProductsView all products

- Mould Reed Switch

- Reed Relay

- Proximity switch/sensor

- Float Level Switch/Water Level Switch

- Liquid Level Sensor

- Flow Switch

- Flow Sensor

- Gas flow switch/sensor

- Pressure Switch

- Pressure Sensor

- Water Detection/Leak Sensor

- Temperature Switch

- Temperature Sensor

- Tilt switch

- Acceleration&Shock Switch

- Cylinder Magnetic Sensor

- Component Parts of Sensors

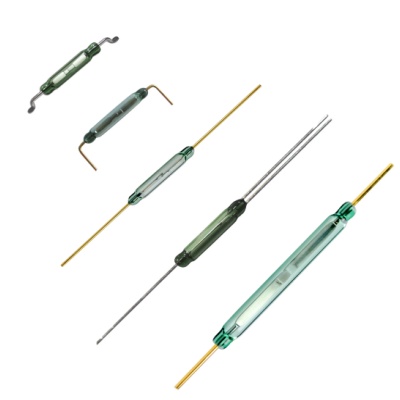

- Reed Switch

SIP Mould Reed Switch Series

When a magnet or coil creates a magnetic field that acts on the switch, both reeds of the reed switch become magnetized. An N pole is formed on the contact point of one of the reeds, and an S pole is formed on the contact point of the other reed. If the attractive force of the generated magnetic field causes the contacts to conduct, the circuit is closed. Once the magnetic field weakens to a certain extent, the reeds will separate again due to elastic force, which means the circuit is disconnected.

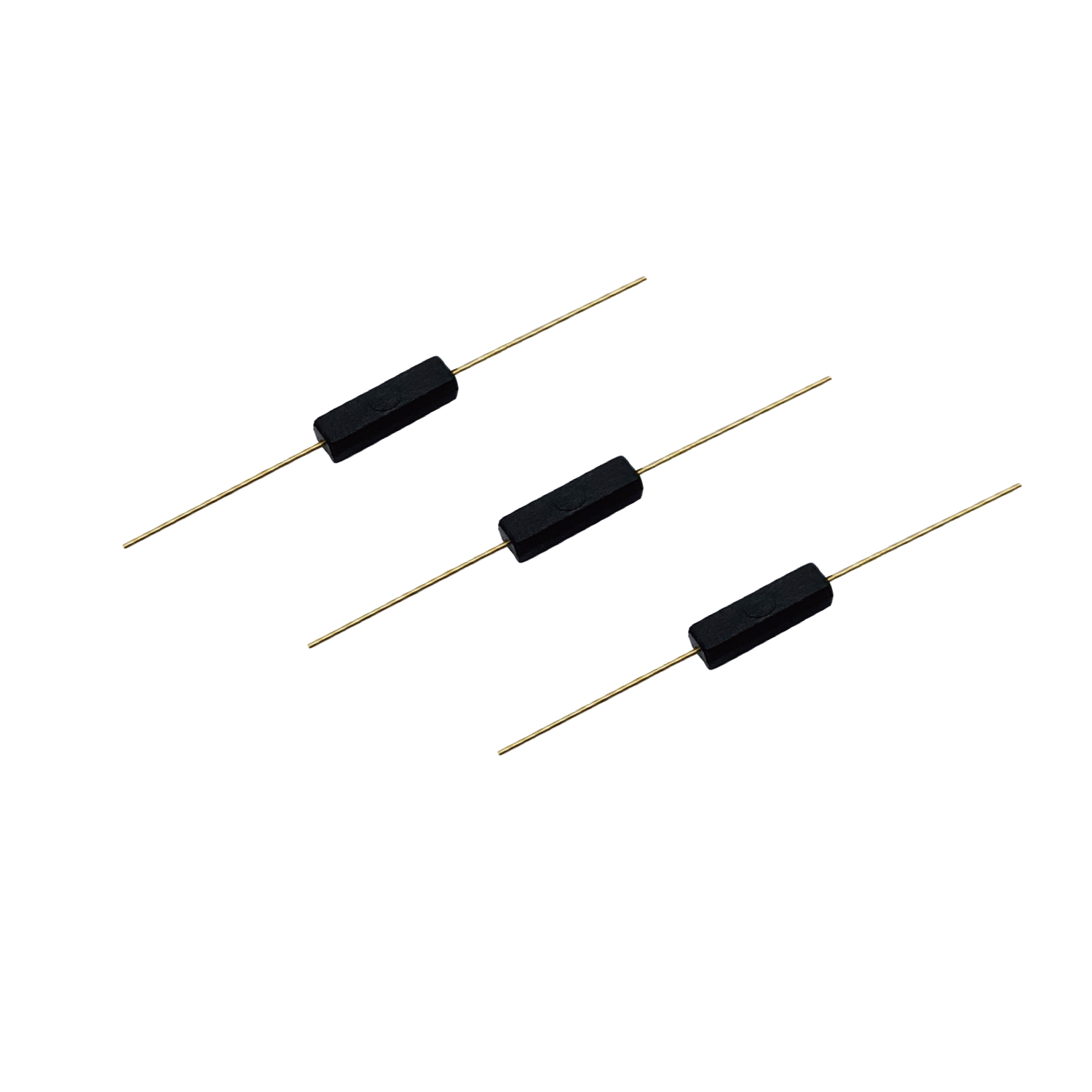

Line Mould Reed Switch

When a magnet or coil creates a magnetic field that acts on the switch, both reeds of the reed switch become magnetized. An N pole is formed on the contact point of one of the reeds, and an S pole is formed on the contact point of the other reed. If the attractive force of the generated magnetic field causes the contacts to conduct, the circuit is closed. Once the magnetic field weakens to a certain extent, the reeds will separate again due to elastic force, which means the circuit is disconnected.

SMD Mould Reed Switch Series

When a magnet or coil creates a magnetic field that acts on the switch, both reeds of the reed switch become magnetized. An N pole is formed on the contact point of one of the reeds, and an S pole is formed on the contact point of the other reed. If the attractive force of the generated magnetic field causes the contacts to conduct, the circuit is closed. Once the magnetic field weakens to a certain extent, the reeds will separate again due to elastic force, which means the circuit is disconnected.

Reed Relay

A reed relay is a relay that uses a coil to generate a magnetic field to actuate a reed tube. It is a coil sensing device. Therefore, the characteristics of reed relays are small size, light weight, fast response speed, short bounce time and other characteristics. Mainly used in measurement equipment, communication equipment, security equipment, medical equipment, etc.

Industrial Relay

The main function of the relay is amplification. With a very small current, a circuit with a large power can be controlled, and the control range can also be expanded. When the signal reaches a certain value, the contacts can be switched simultaneously according to different forms of the contact group. Open and connect multiple circuits to achieve the purpose of automatic switching.

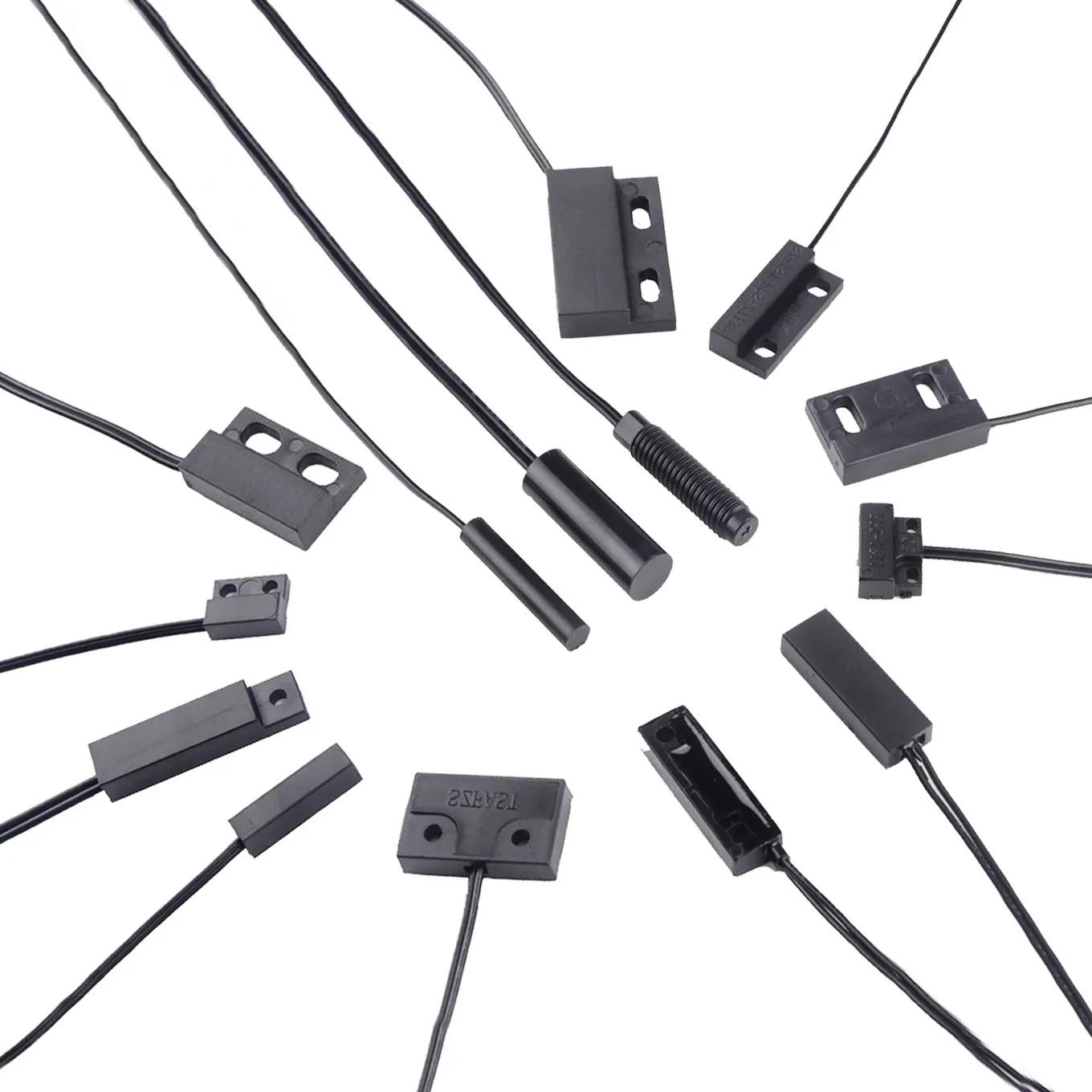

Magnetic Reed Type

Proximity switch/proximity sensors are widely used in various household appliances, security systems, access control systems, safety interlocks, position positioning, and equipment automation.

Hall Type

Hall type proximity switch is composed of a reed switch and a permanent magnet. They are individually enclosed in a plastic housing for protection and ease of installation.

SCR/MOSFET Type

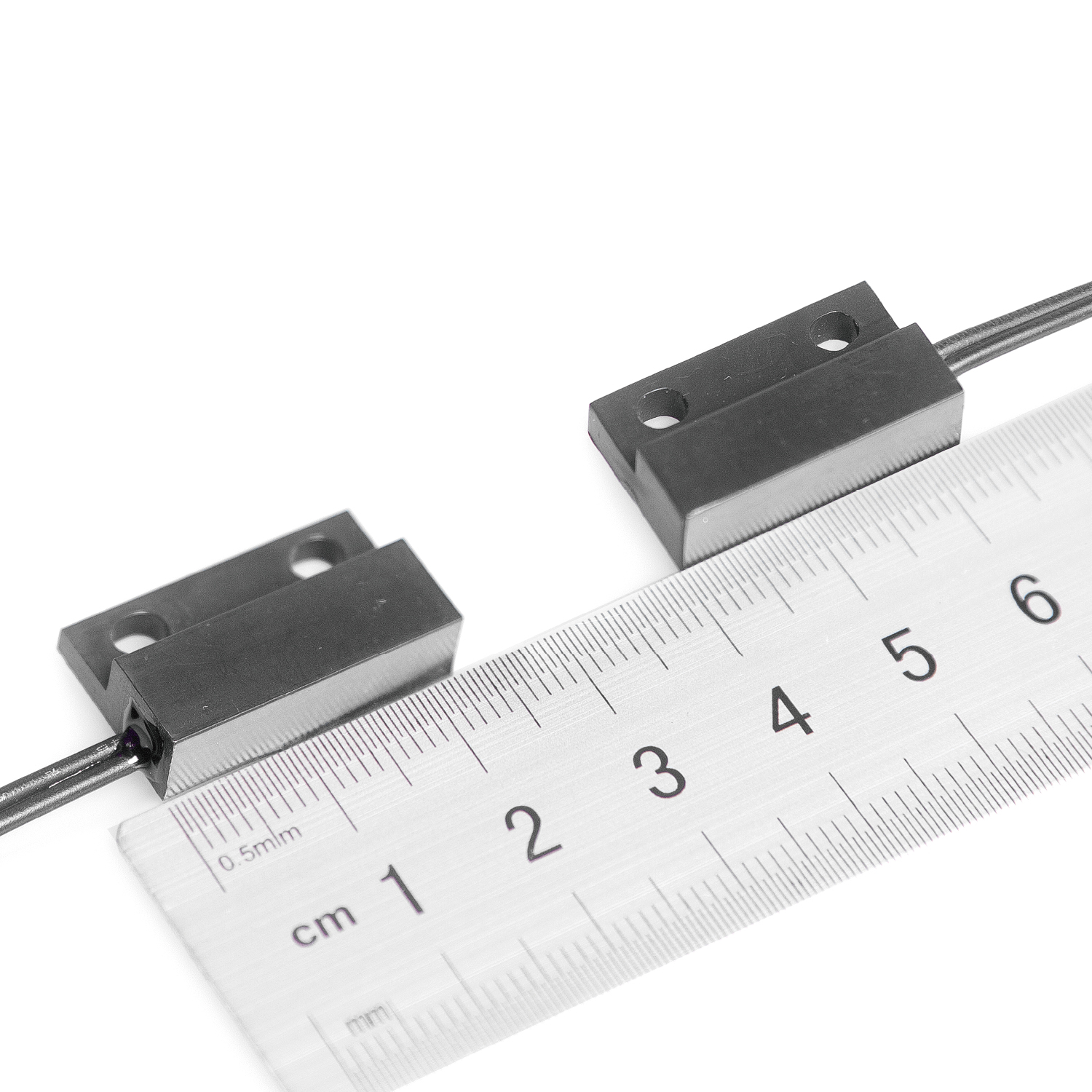

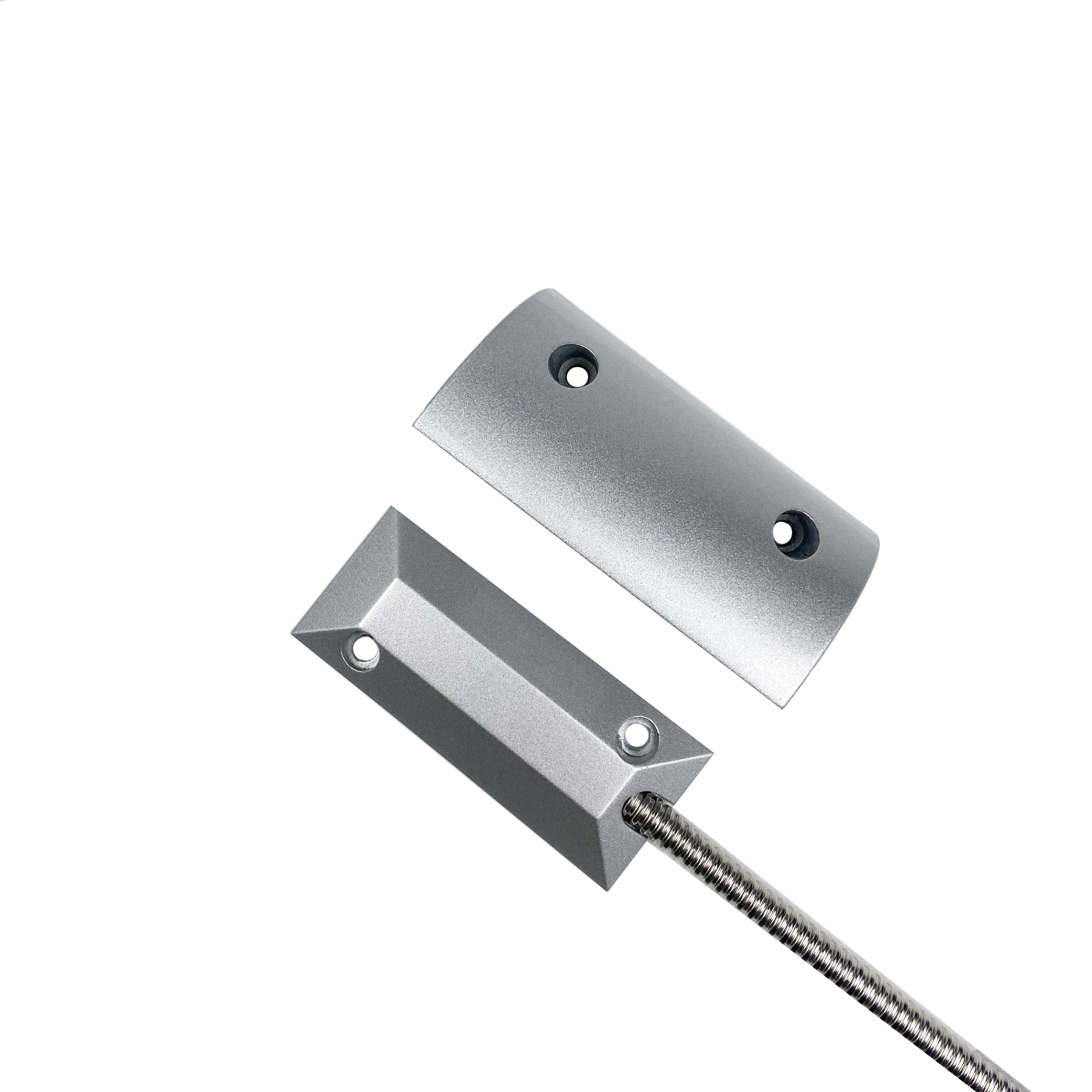

Magnetic Door Type

Proximity switches/proximity sensors are widely used in various household appliances, security systems, access control systems, safety interlocks, position positioning, and equipment automation.

Photoelectric Type

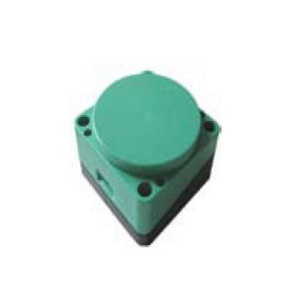

Inductive Type

Proximity switches/proximity sensors are therefore widely used in various household appliances, security systems, access control systems, safety interlocks, position positioning, and equipment automation.

Dual-stable reed switch

Plastic Materials

Widely used in the control of water tanks, compressors and pumps, household appliances, medical equipment, industrial braking, petrochemicals, food processing, electric power, public works, vehicles and ships, etc.

Stainless Steel Series

Widely used in the control of Water Tanks, Compressors and Pumps, Household Appliances, Industry Automation, Medical Equipment, Petrochemical Industry, Power, Food Processing, Public Engineering, Vehicles and Ships etc.

Special Water Level Switch

Photoelectric Liquid Level Sensor

FAST can provide customized wide-range sensors with up to 7 set points and lengths from 20mm to 2m. The valve stem and float can be made of stainless steel, PP, NBR and other materials.

4-20mA Current output

Widely used in the control of water tanks, compressors and pumps, household appliances, medical equipment, industrial automation, petrochemicals, food processing, electricity, public works, vehicles and ships, etc.

0-5V Voltage output

Widely used in the control of water tanks, compressors and pumps, household appliances, medical equipment, industrial automation, petrochemicals, food processing, electricity, public works, vehicles and ships, etc.

Plastic Flow Switch

All FAST flow sensors and flow switches are made of high-quality corrosion-resistant materials to ensure good performance in harsh environments. They are made from materials ranging from stainless steel to engineering plastics and are highly chemically compatible.

Stainless Steel Flow Switch

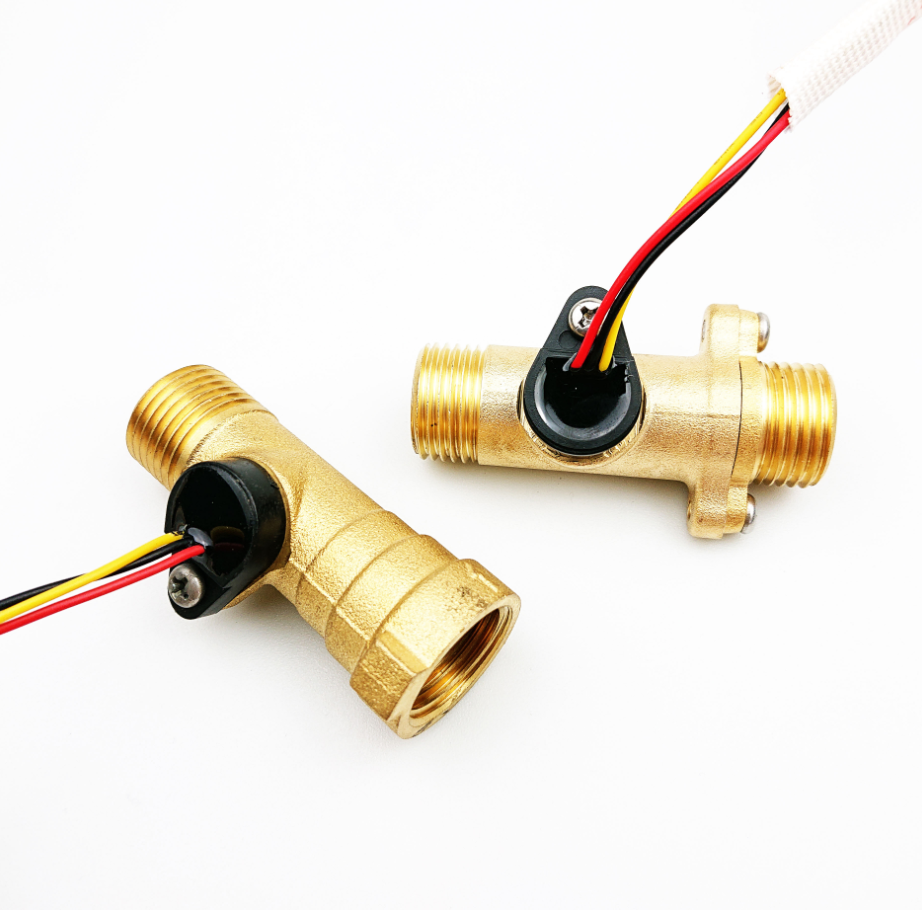

FAST flow sensors and flow switches are commonly used in applications such as rotating equipment, conveyors, gas sampling and distillation, water purification systems, welding machines, semiconductor equipment, chemical processing, machine tools and robotics.

Brass Flow Switch

Plastic Flow Sensor

FAST flow sensors and flow switches are commonly used in applications such as rotating equipment, conveyors, gas sampling and distillation, water purification systems, welding machines, semiconductor equipment, chemical processing, machine tools and robotics.

Stainless Steel Flow Sensor

All FAST flow sensors and flow switches are made of high-quality corrosion-resistant materials to ensure good performance in harsh environments. They are made from materials ranging from stainless steel to engineering plastics and are highly chemically compatible.

Brass Flow Sensor

4-20mA Current output

Plastic Pressure Switch

When the pressure in the system is higher or lower than the rated safety pressure, the disc in the sensor moves instantaneously, and the switch joint is turned on or off through the connecting rod. When the pressure drops or rises to the rated recovery value, The disc instantly resets and the switch automatically resets, or simply put, when the measured pressure exceeds the rated value, the free end of the elastic element is displaced, pushing the switch element directly or after comparison, changing the on-off state of the switch element, to achieve The purpose of controlling the measured pressure.

Brass Pressure Switch

Stainless Steel Pressure Switch

When the pressure in the system is higher or lower than the rated safety pressure, the disc in the sensor moves instantaneously, and the switch connector is pushed on or off through the connecting guide rod. When the pressure drops to or rises to the rated recovery value, the disc resets instantly and the switch resets automatically. In simple terms, when the measured pressure exceeds the rated value, the free end of the elastic element is displaced, and the switch element is pushed directly or after comparison, changing the on-off state of the switch element to achieve the purpose of controlling the measured pressure.

Probe Water Leak Detection Sensor

When a water leak occurs in a facility or equipment and water contacts both electrodes of the sensor at the same time, it will trigger the relay in the sensor to work and control the external alarm or water pump, solenoid valve and other equipment connected to it.

Photoelectric Water Leak Sensor

Temperature switch sensor

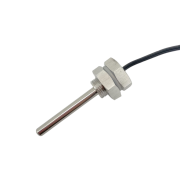

Temperature Sensor NTC

Temperature sensor products have stable performance, reliability and long life;NTC uses a temperature chip with a curve β value of ±1% and a resistance R value accuracy of ±1%. The outer casing is made of stainless steel 304 or nickel-plated copper, and is encapsulated with high-temperature epoxy resin. It can operate in harsh industrial environments;

Temperature Sensor-PT100

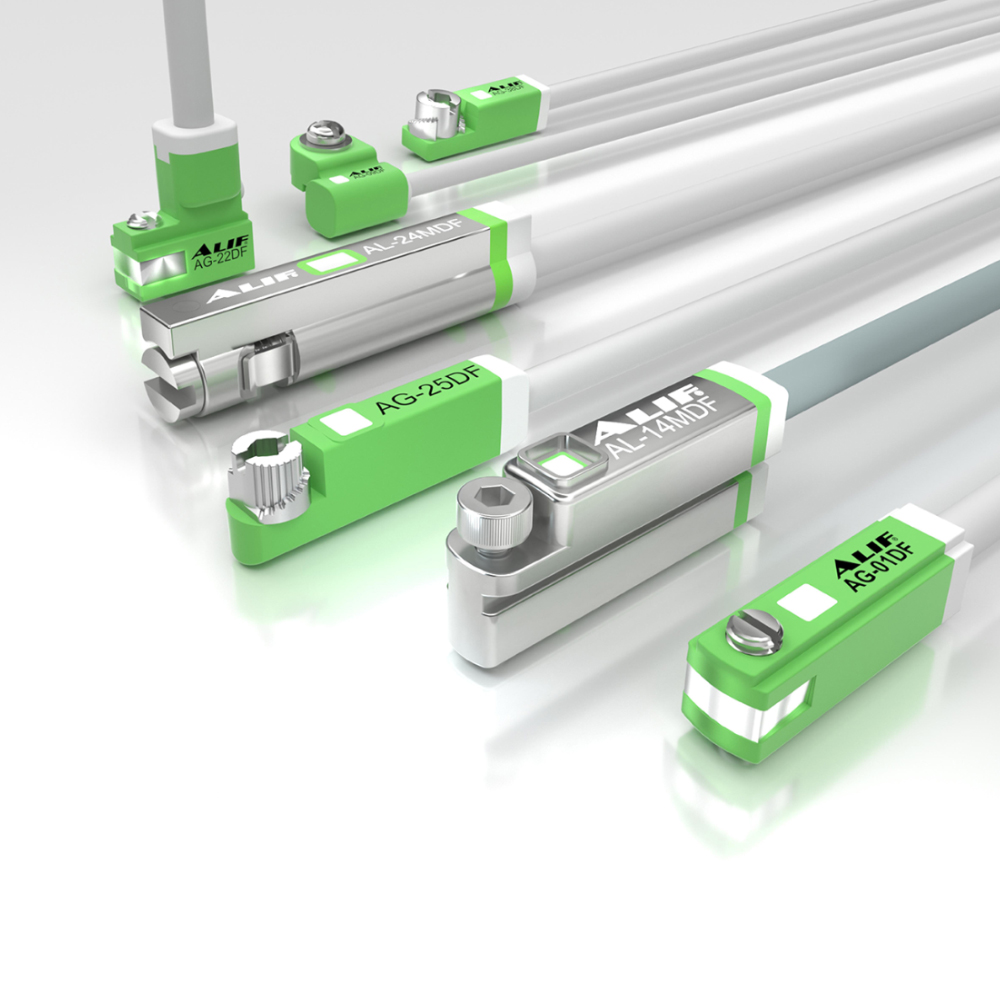

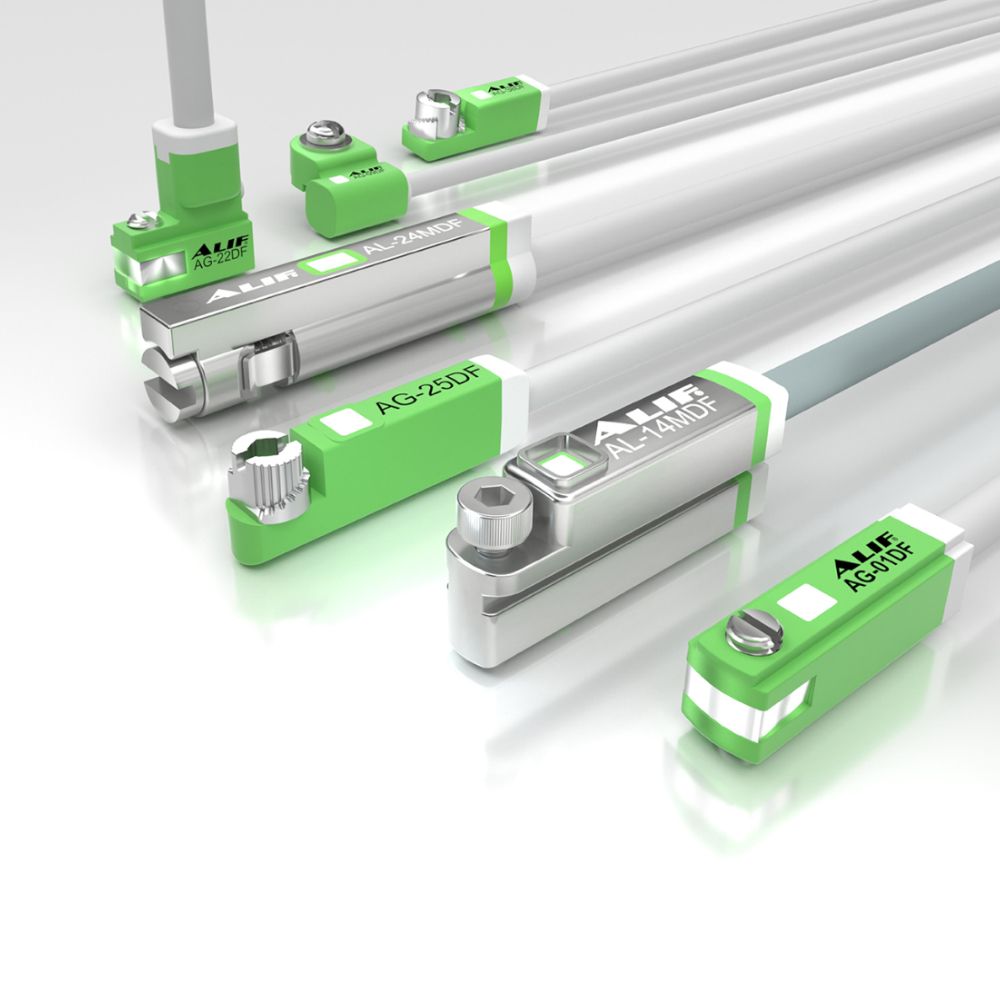

Reed Type Cylinder Magnetic Sensor

A variety of specifications are available, excellent material is wear-resistant, corrosion-resistant, not easy to damage, and long-lasting

Hall Type Cylinder Magnetic Sensor

COTO RI

The advantages of compact structure, light weight, fast response time, long life and low cost. They are widely used in household appliances, industrial products, medical equipment, toys, fitness equipment, security, intelligent control, reed relays and other devices.

COMUS GC

Reed switches have contact types of normally open (Form A), normally closed (Form B) and normally closed normally open conversion (Form C). They are triggered by the magnetic field generated by a permanent magnet or a current-carrying coil.

STANDEX ORD

Reed switch consists of an elastic reed of magnetic material that is sealed in a glass tube filled with inert gas. The end faces of the magnetic sheets overlap but there is a certain gap in the middle, and the end face contacts are plated with a layer of precious metals (such as rhodium, ruthenium, etc.). Increases the stability of the switch and extends the service life of the machine.

DOLAM ZP

Reed switch consists of an elastic reed of magnetic material that is sealed in a glass tube filled with inert gas. The end faces of the magnetic sheets overlap but there is a certain gap in the middle, and the end face contacts are plated with a layer of precious metals (such as rhodium, ruthenium, etc.). Increases the stability of the switch and extends the service life of the machine.

ALEPH HYR

Reed switch consists of an elastic reed of magnetic material that is sealed in a glass tube filled with inert gas. The end faces of the magnetic sheets overlap but there is a certain gap in the middle, and the end face contacts are plated with a layer of precious metals (such as rhodium, ruthenium, etc.). Increases the stability of the switch and extends the service life of the machine.

LITTELFUSE MDSR

Reed switches have contact types of normally open (Form A), normally closed (Form B) and normally closed normally open conversion (Form C). They are triggered by the magnetic field generated by a permanent magnet or a current-carrying coil.

- Cases

Smart Home

While you are still on your way, you can remotely turn on various household appliances, so that When you get home, there will be a comfortable and warm home waiting for you.

Industrial Automation

Intelligent control and operation maintenance of the entire process of industrial manufacturing to improve production efficiency and quality, reduce energy consumption, and ensure production safety

Automotive Field

The company can provide professional high-voltage interconnection solutions for new energy vehicles.

Smart Healthcare

The company can provide interconnection solutions such as mixed high and low frequency, mixed photoelectric, high life module connectors, and high voltage cable assemblies medical equipment.

Instruments Meters

In harsh conditions, carry out reliable data measurement, accurately predict machine failures, maintain equipment health, improve productivity, and reduce maintenance costs

Security Equipment

Security sensors are an indispensable part of safety monitoring systems. They can perceive changes in the surrounding environment and transmit this information to...

Semiconductor

Semiconductor fabrication is a complex and delicate process where even the slightest deviation can impact yield and quality. Sensors act as the watchful eyes of this operation, providing real-time data that traditional methods can't capture. This all

Consumer Electronics

Sensors are the secret behind the magic of modern electronics. They convert physical data from the environment—like motion, light, sound, and pressure—into digital information that a device can understand and use. This enables a seamless and intuitive use

- News & Events

- Contact Us

- Mould Reed Switch

- MODEL Reed SwitchSIP Mould Reed Switch SeriesLine Mould Reed SwitchSMD Mould Reed Switch Series

- Reed Relay

- Reed RelayIndustrial Relay

- Proximity switch/sensor

- Magnetic Reed TypeHall TypeSCR/MOSFET TypeMagnetic Door TypePhotoelectric TypeInductive TypeDual-stable reed switch

- Float Level Switch/Water Level Switch

- Plastic MaterialsStainless Steel SeriesSpecial Water Level SwitchPhotoelectric Liquid Level Sensor

- Liquid Level Sensor

- 4-20mA Current output0-5V Voltage output

- Flow Switch

- Plastic Flow SwitchStainless Steel Flow SwitchBrass Flow Switch

- Flow Sensor

- Plastic Flow SensorStainless Steel Flow SensorBrass Flow Sensor4-20mA Current output

- Gas flow switch/sensor

- Pressure Switch

- Plastic Pressure SwitchBrass Pressure SwitchStainless Steel Pressure Switch

- Pressure Sensor

- Water Detection/Leak Sensor

- Probe Water Leak Detection SensorPhotoelectric Water Leak Sensor

- Temperature Switch

- Temperature Sensor

- Temperature switch sensorTemperature Sensor NTCTemperature Sensor-PT100

- Tilt switch

- Tilt Switch / Ball Switch SensorAngle Sensor

- Acceleration&Shock Switch

- Acceleration SwitchShock SwitchSpeed Switch

- Cylinder Magnetic Sensor

- Reed Type Cylinder Magnetic SensorHall Type Cylinder Magnetic Sensor

- Component Parts of Sensors

- Float BallHoured MagnetPCB PartsStainless steel parts

- Reed Switch

- COTO RICOMUS GCSTANDEX ORDDOLAM ZPALEPH HYRLITTELFUSE MDSR

- Smart Home

- Smart home solution

- Industrial Automation

- Industrial automation solution

- Automotive Field

- Automotive field solution

- Smart Healthcare

- Smart healthcare solution

- Instruments Meters

- Instrumentation Solutions

- Security Equipment

- Security surveillance solution

- Semiconductor

- Solutions for the semiconductor field

- Consumer Electronics

- Consumer electronics solutions

Products

PRODCTS

Temperature switch sensor

Mould Reed Switch (44)

Reed Relay (21)

Proximity switch/sensor (60)

Float Level Switch/Water Level Switch (53)

Liquid Level Sensor (8)

Flow Switch (34)

Flow Sensor (34)

Gas flow switch/sensor (4)

Pressure Switch (21)

Pressure Sensor (8)

Water Detection/Leak Sensor (9)

Temperature Switch (4)

Temperature Sensor (6)

Tilt switch (6)

Acceleration&Shock Switch (6)

Cylinder Magnetic Sensor (11)

Component Parts of Sensors (8)

Reed Switch (51)

Temperature Sensor

Shell material: SUS304;,Size: Various sizes available (customizable);,Standard line length: 200mm (customizable);,Temperature range: -40℃~+150℃;

Copyright © 2025 Fast Sensor HongKong Limited .